Cauhé puzzles machine

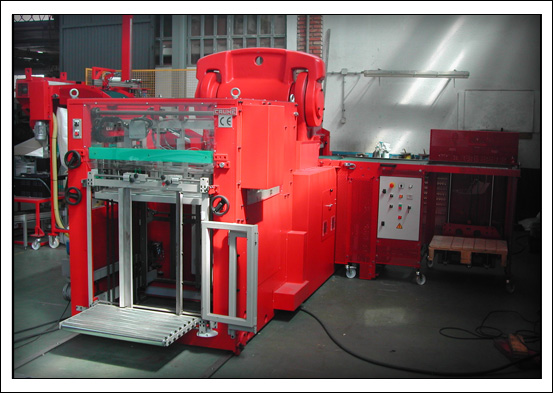

The Cauhé puzzles and jigsaw machine ( POWERPRESS ) is a special version of our diecutters that has been specifically designed for compact cardboard punching dies with the shape of a puzzle, although it admits all kinds of dies

Unlike our clamshell die cutters which have a book opening movement and loading and unloading of the material to be punched is provided at the front of the machine, Cauhé puzzles machine have a vertical movement, so that the material to be punched is positioned above the cutting plate on the front of the machine being automatically introduced into the press and ejected from the back, going to the next stage of the manufacturing process. In this way the operator only has to take care of introducing the material in single stroke mode or timed mode previously set

If a puzzle is too big to be punched in one machine stroke and must be done in two strokes, you can install a semi-diecut stacker to finish the job later. For some customers who prefer to do puzzles with many blades in one stroke, the machine can be strengthened. If this is the case or have any preference for your job please contact us.

Models and formats

We mainly manufacture 2 models

- 53x73 cms

- 72x102 cms

![]() Any other size or model can be manufactured on demand.

Any other size or model can be manufactured on demand.

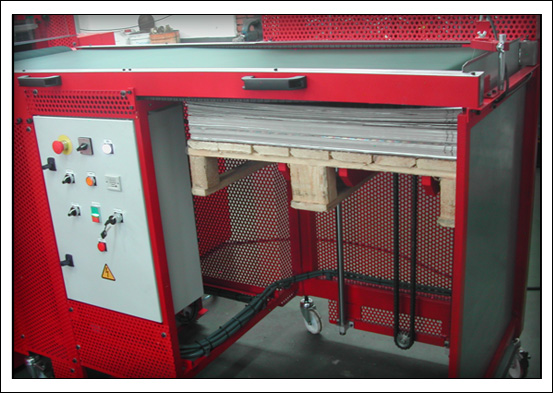

Puzzles machine options

We have several options for our puzzles diecutter. Among all we highlight the following:

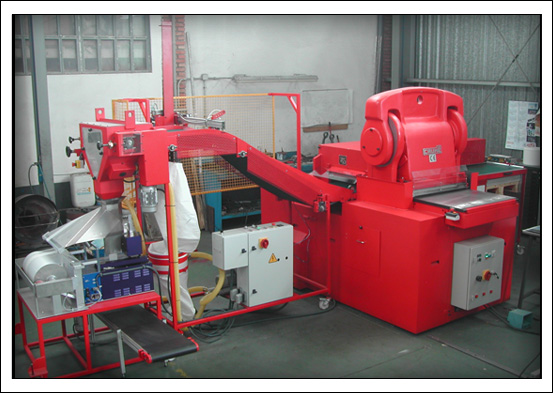

Installing an automatic feeder capable of carrying the puzzles machine at full speed you will obtain best performance working without downtime. This automatic feeder can be manually separated from the main body to prepare the machine or working in manual mode.

The machine can be manufactured to work with double feed, an operator or automatic feeder feeds the front and another does from the back, winning around 40% of production.

The missing piece verification system is easy to adjust for each job and detects by an optical camera that digitally checks the punched puzzle if there has been a loose piece during cutting and does not leave the die with the rest of the puzzle. If a part is missing gives an alarm signal to the machine before the next stroke and discards the puzzle.

Some companies prepare the puzzle before die cutting the puzzle cutting the frame and other companies die cut the puzzle with the frame and then extract it.

With our frame extractor system, a must have option for companies that do not guillotine the material prior to die cut the puzzle, the frame is automatically removed from the production line while the punched puzzle travels in the conveyor belt to the next stage: the chop up device, the bagging system, etc. So with this option you don´t need to have a paper cutter guillotine for this purpose and reduce the production time.

After the puzzle is die cutted, the puzzle travels over a conveyor belt to the chop-up device, which is the system that dismantles the die cutted puzzle into small pieces and then can be taken to the next production line stage, mainly the bag sealer. By automating the process time and costs are reduced.

Once the puzzle is dismantled, the bagging system collects all the pieces in a plastic bag hot sealed so that no piece will get lost

With the bagging system can be installed, if necessary, a printer for labeling bags with the reference of each puzzle and a high precision weight for detecting incomplete bags and a system of separation unfit bags.

Using a high precision digital weight configurable by the user the puzzle can be weighed and if there is a difference in grams equivalent to the weight of a piece the puzzle is discarded. In this way we ensure that no piece has been lost during the die cutting production line.

If you want to have automatic bagger or any peripherals connected to the bagging system, the chop-up device has to be in upper version.